Vónin

It all started in 1969 and today Vónin is a major developer and manufacturer of high quality fishing gear, aquaculture equipment as well as supplying equipment for the land base industry.

Back

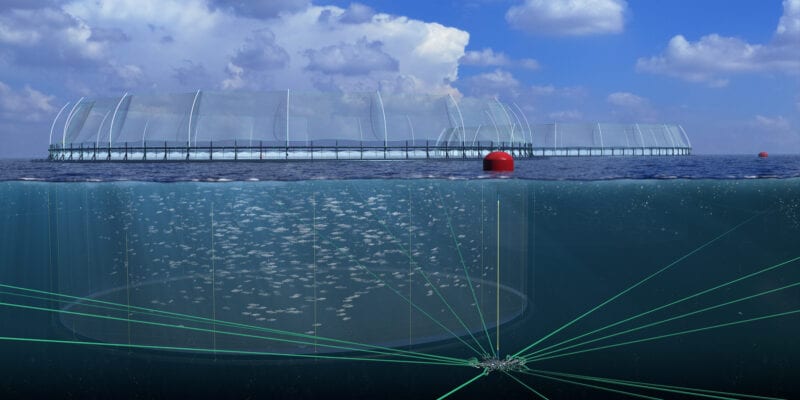

We have decades of experience in designing, developing and manufacturing cage nets for the aquaculture industry. This has enabled us to supply fish farmers with high quality and durable cage nets.

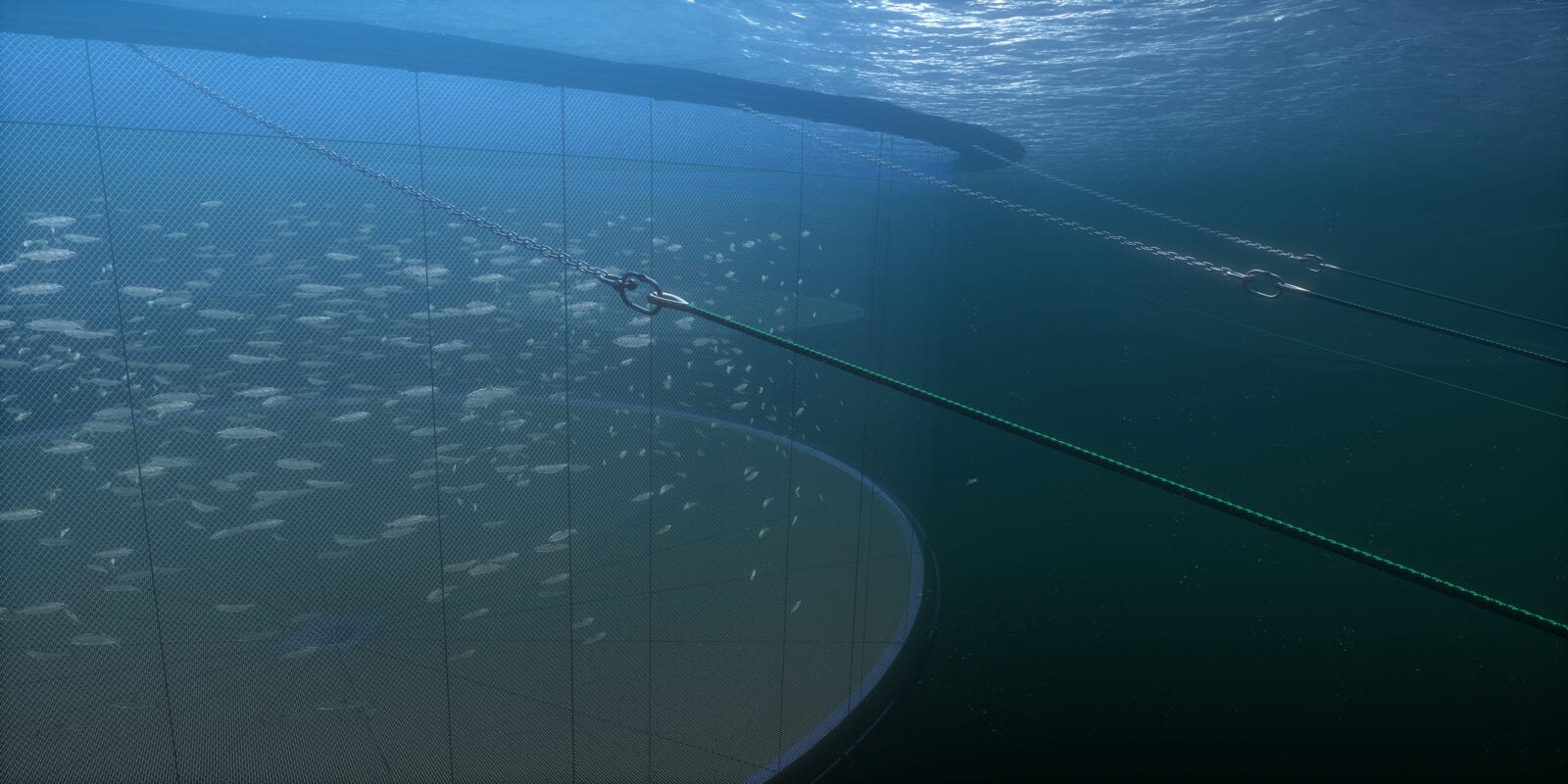

Everything from the fabric to the structure of the net is carefully considered and continuously developed in close collaboration with fish farmers. Our cage net designs are thoroughly tested to withstand the harsh environment of the North Atlantic.

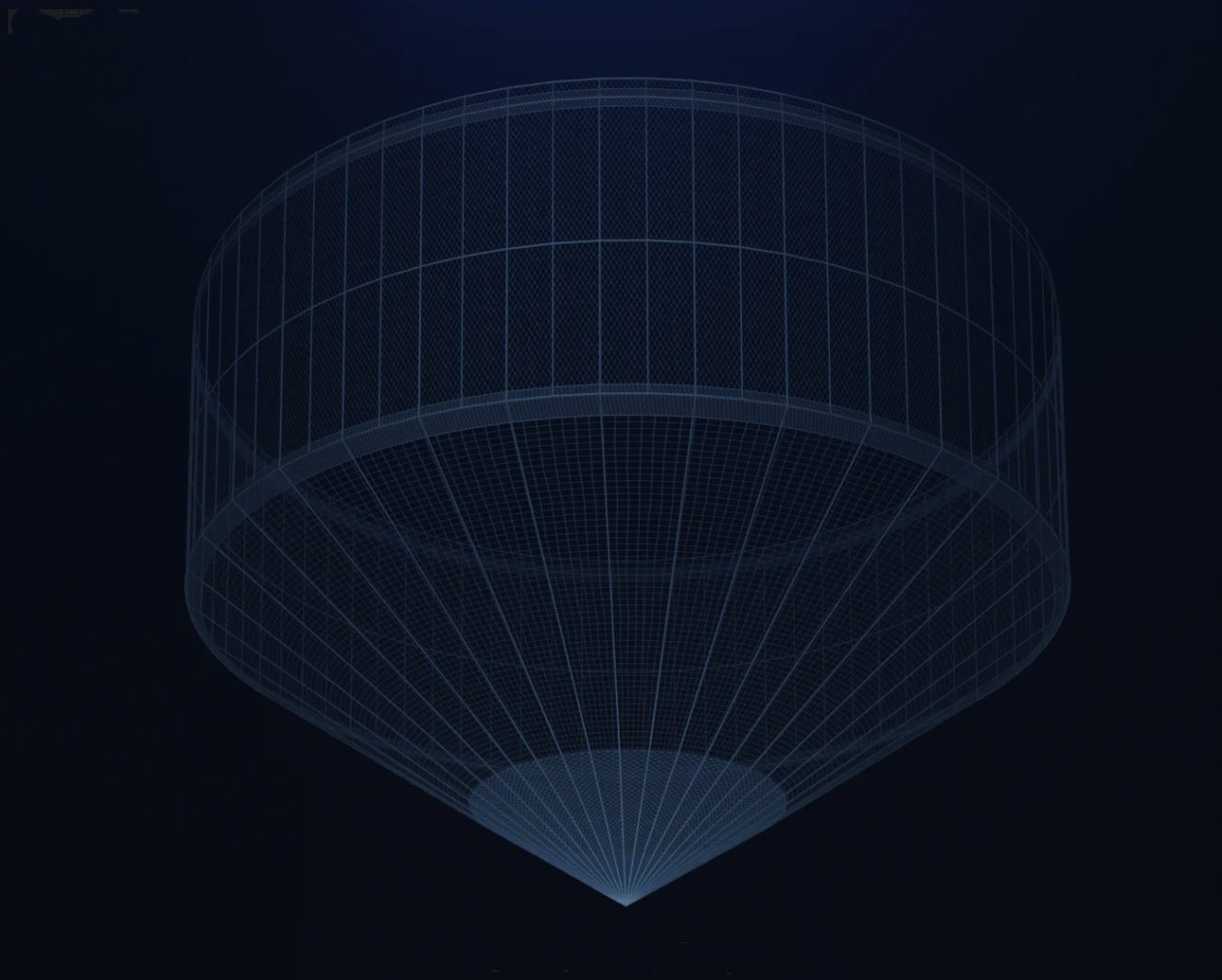

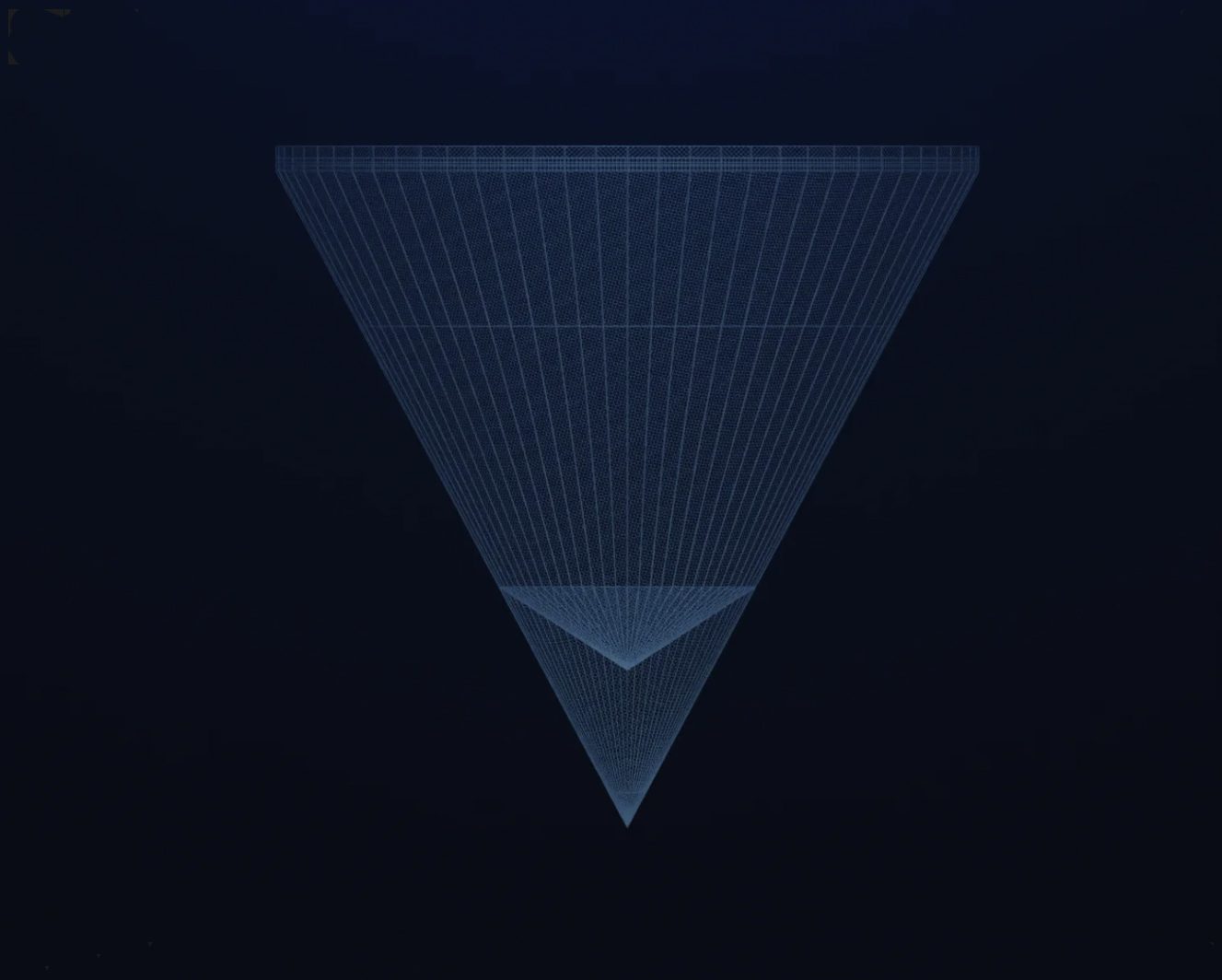

Bottom of the nets is designed in a way that dead fish can be easily collected.

Exposed spots in the cage nets are identified and reinforced to increase safety and reduce fish escape.

Strong center ring lasts the lifetime of the cage nets, which means less maintenance costs.

Quick and easy to install and handle.

Less maintenance than industry standard.

Short delivery time.

Certified according to NS9415 standards.

With our ongoing development process and with the most advanced and newest machines we have managed to construct high quality Dyneema and nylon netting with minimal shrinkage. This leads to:

Better performance in the sea.

Less repairs required.

Better durability.

Better fit, which also makes it easier for the washing robots.

We offer a variety type of high quality netting depending on needs and site specifications.

Our Dyneema cage nets are of highest quality. Dyneema is an incredibly strong material, which allows for a much thinner twine compared to other materials. This has several benefits:

Nylon netting is by tradition the most used type of netting for cage nets.

The HDPE netting is well suited when net cleaning robots are the most used method for washing the nets.

Engineered with high-performance fibers, the advanced Royal netting provides exceptional predator protection. Its antifouling properties ensure optimal performance, keeping your fish secure and thriving. With Royal, you gain access to a suit of exceptional features that ensure unparalleled performance.

Wave height, currents, weather and seabed conditions differ dramatically in many of the fish farming areas and therefore the requirements for top performance in terms of cage nets are diverse.

Basically we have four different designs, but the fish farmers have the opportunities to take advantage of the experience Vónin has at its disposal, with the cage nets custom-designed and built to suit each fish farmer’s requirements and the conditions on the farming sites.

CIRCULAR

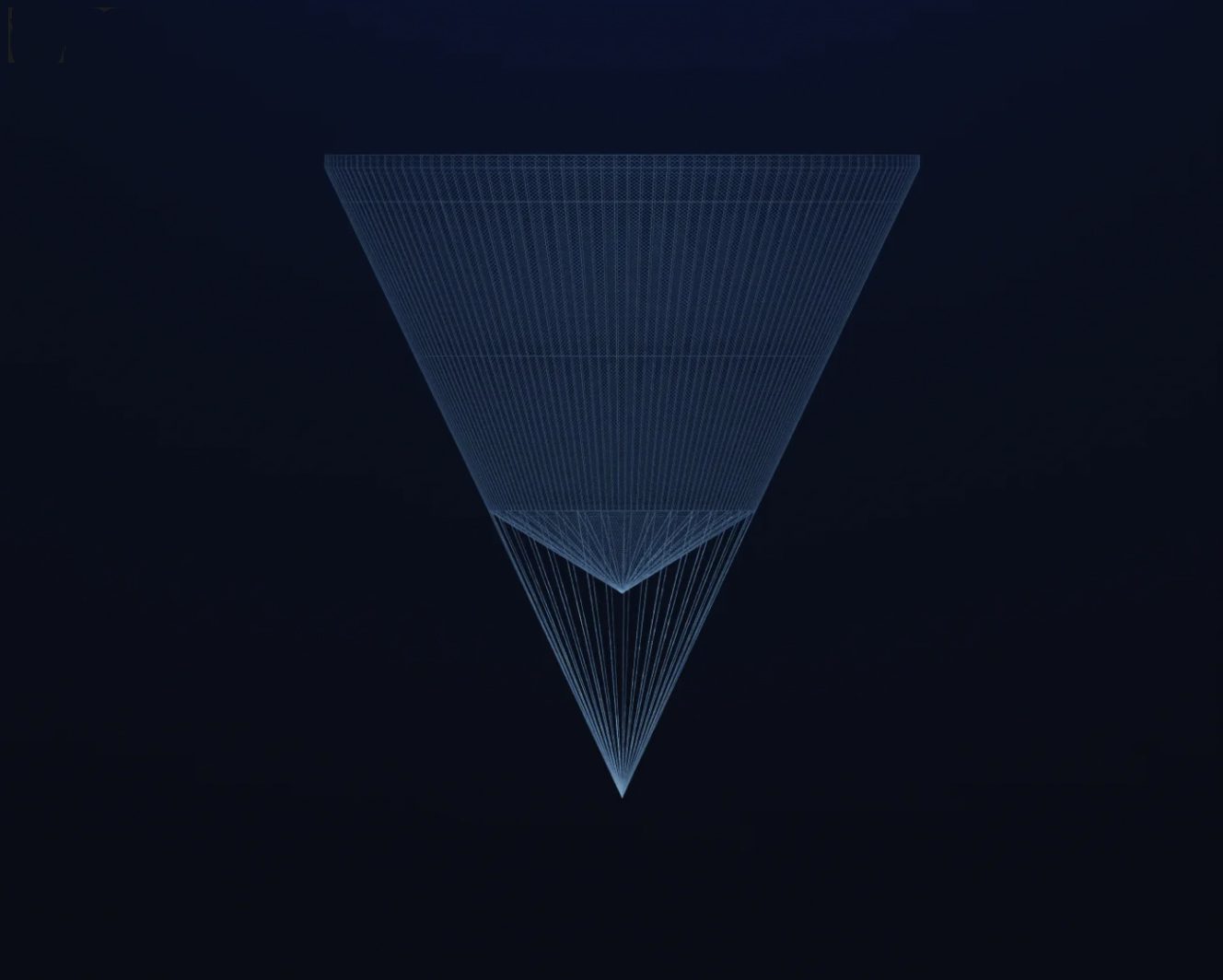

POINTED

SPAGHETTI

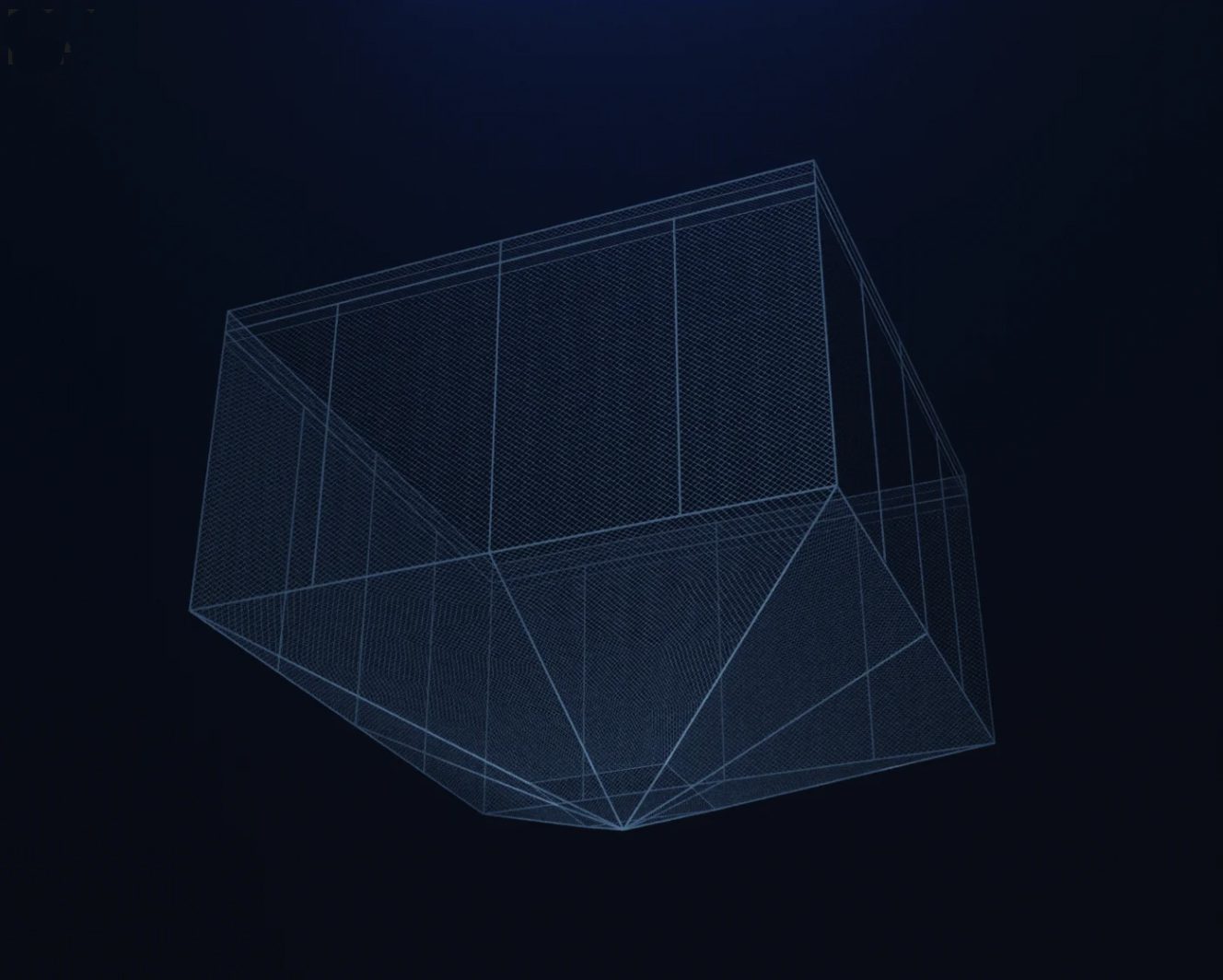

SQUARE